Unleashing Excellence in Metal Fabrication: A Deep Dive into China's Premier Lathe Machining Parts Factory

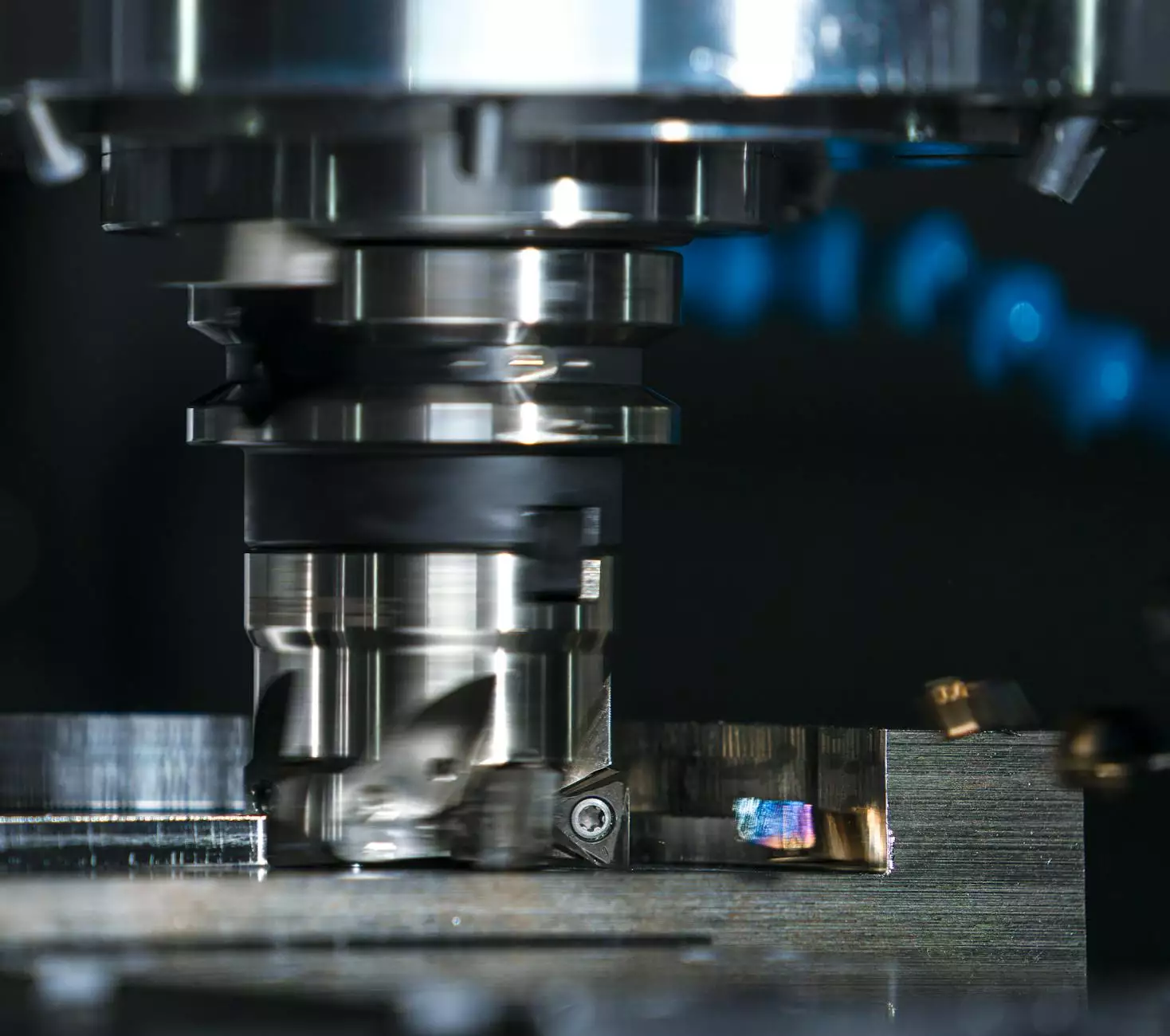

In the rapidly evolving landscape of modern manufacturing, the demand for high-precision, reliable, and cost-effective metal fabrication solutions has never been greater. As industries ranging from aerospace to automotive, electronics to heavy machinery seek components that meet exact specifications, the role of specialized factories becomes paramount. DeepMould.net, acknowledged as a leading metal fabricator and a top-tier china lathe machining parts factory, stands at the forefront of this technological frontier, delivering exceptional quality and innovation in every product we craft.

Why Choosing a Leading China Lathe Machining Parts Factory Matters

Working with an esteemed china lathe machining parts factory confers numerous advantages. From precision engineering and rapid turnaround times to cost savings and customization capabilities, the benefits are profound:

- Unmatched Precision: Advanced CNC lathe machines enable the manufacture of intricately detailed components with tight tolerances, essential for sectors like aerospace and medical devices.

- Cost Efficiency:Productivity enhancements, bulk manufacturing, and optimized supply chains reduce overall costs without compromising quality.

- Customization and Flexibility: Whether prototyping or large-volume production, Chinese factories excel in tailoring solutions to specific customer requirements.

- Rapid Lead Times: Lean manufacturing practices and local supply channels facilitate faster delivery schedules, empowering businesses to accelerate time-to-market.

- Global Standards Compliance: Top Chinese factories conform to international quality standards such as ISO 9001, ensuring reliability and consistency across all outputs.

DeepMould.net’s Commitment to Excellence in Metal Fabrication

At DeepMould.net, our mission is to provide comprehensive and cutting-edge solutions in metal fabrication. Our expertise as a leading china lathe machining parts factory is rooted in decades of experience, state-of-the-art technology, and a dedicated team of skilled engineers. We specialize in delivering components with complex geometries, fine surface finishes, and robust structural integrity.

Our Core Capabilities in Lathe Machining

- Precision Turning: High-speed CNC lathes produce cylindrical, conical, and complex turned parts with tolerances as tight as ±0.005 mm.

- Automated Multi-Axis Machining: Multi-axis CNC machines enable complex, multifaceted component manufacturing with minimal setup times.

- Material Diversity: Expertise in working with various metals such as steel, brass, aluminum, titanium, and specialty alloys to match application needs.

- Surface Finishing: Processes including polishing, deburring, anodizing, and coating enhance both functionality and aesthetics.

- Quality Control: Rigorous inspection protocols employing coordinate measuring machines (CMM) and other advanced metrology ensure batch consistency and adherence to customer specifications.

The Importance of Quality and Precision in Metal Fabrication for Business Success

In today’s competitive global markets, the quality of machined parts is a critical determinant of product reliability, customer satisfaction, and brand reputation. Choosing a china lathe machining parts factory like DeepMould.net guarantees:

- Consistent Product Quality: Tight controls and advanced machinery reduce variability.

- Enhanced Durability and Performance: Precisely machined components perform better over their lifespan.

- Reduced Production Waste: Efficient machining processes minimize material wastage and rework costs.

- Compliance with Industry Standards: Certification and adherence to international quality norms facilitate global business expansion.

Innovative Metal Fabrication Solutions for Diverse Industries

Our factory’s versatility allows us to serve a wide array of sectors:

- Aerospace: High-precision turbine blades, avionics components, and structural parts.

- Automotive: Engine components, transmission parts, and custom chassis elements.

- Electronics: Miniature connectors, housings, and heat sinks.

- Medical Devices: Surgical instruments, implants, and diagnostic equipment.

- Heavy Machinery: Gearboxes, shafts, and structural supports.

Process Workflow at DeepMould.net: From Concept to Final Product

Our comprehensive process ensures precision, quality, and timely delivery through meticulous stages:

- Design Analysis and Optimization: Collaborating with clients to refine CAD models for manufacturability.

- Material Selection: Recommending optimal materials based on application, strength requirements, and cost considerations.

- Prototype Development: Creating initial samples for testing and validation.

- Mass Production: Utilizing advanced CNC lathe machines for efficient mass manufacturing.

- Quality Inspection: Extensive testing using high-precision measurement tools.

- Packaging and Logistics: Ensuring safe transportation with flexible logistics options worldwide.

Why DeepMould.net Is Your Trusted China Lathe Machining Parts Factory

Choosing the right manufacturing partner is crucial for achieving your business goals. Here's why DeepMould.net should be your go-to factory:

- Decades of Industry Experience: Our history is rooted in delivering excellence in metal fabrication.

- State-of-the-Art Technology: Investment in modern CNC equipment and automation improves efficiency and quality.

- Customer-Centric Approach: Personalized solutions, flexible MOQ, and dedicated support ensure customer satisfaction.

- Global Certifications: Our adherence to ISO standards and other certifications demonstrates our commitment to quality.

- Competitive Pricing: Optimized supply chain and local sourcing allow us to provide high-quality parts at competitive prices.

How to Collaborate with DeepMould.net for Your Machining Needs

Partnering with a premier china lathe machining parts factory like DeepMould.net is straightforward:

- Send us detailed drawings, specifications, or prototypes for initial review.

- Receive a comprehensive quotation with cost breakdown and lead time.

- Collaborate on design adjustments for manufacturability enhancements.

- Approve sample production and initiate mass manufacturing.

- Maintain ongoing communication to ensure deadlines, quality, and scope are met.

Conclusion: Elevate Your Manufacturing Standards with DeepMould.net

In an era where precision, quality, and efficiency define business success, partnering with a dependable china lathe machining parts factory like DeepMould.net offers a distinct competitive advantage. Our commitment to technological innovation, rigorous quality control, and customer-centric service ensures that your components will meet and exceed industry standards. Trust us to transform your ideas into reality with unmatched craftsmanship, helping you thrive in a highly competitive marketplace.

Experience the difference that top-tier metal fabrication can make for your business — contact DeepMould.net today and unlock new opportunities for growth and excellence.